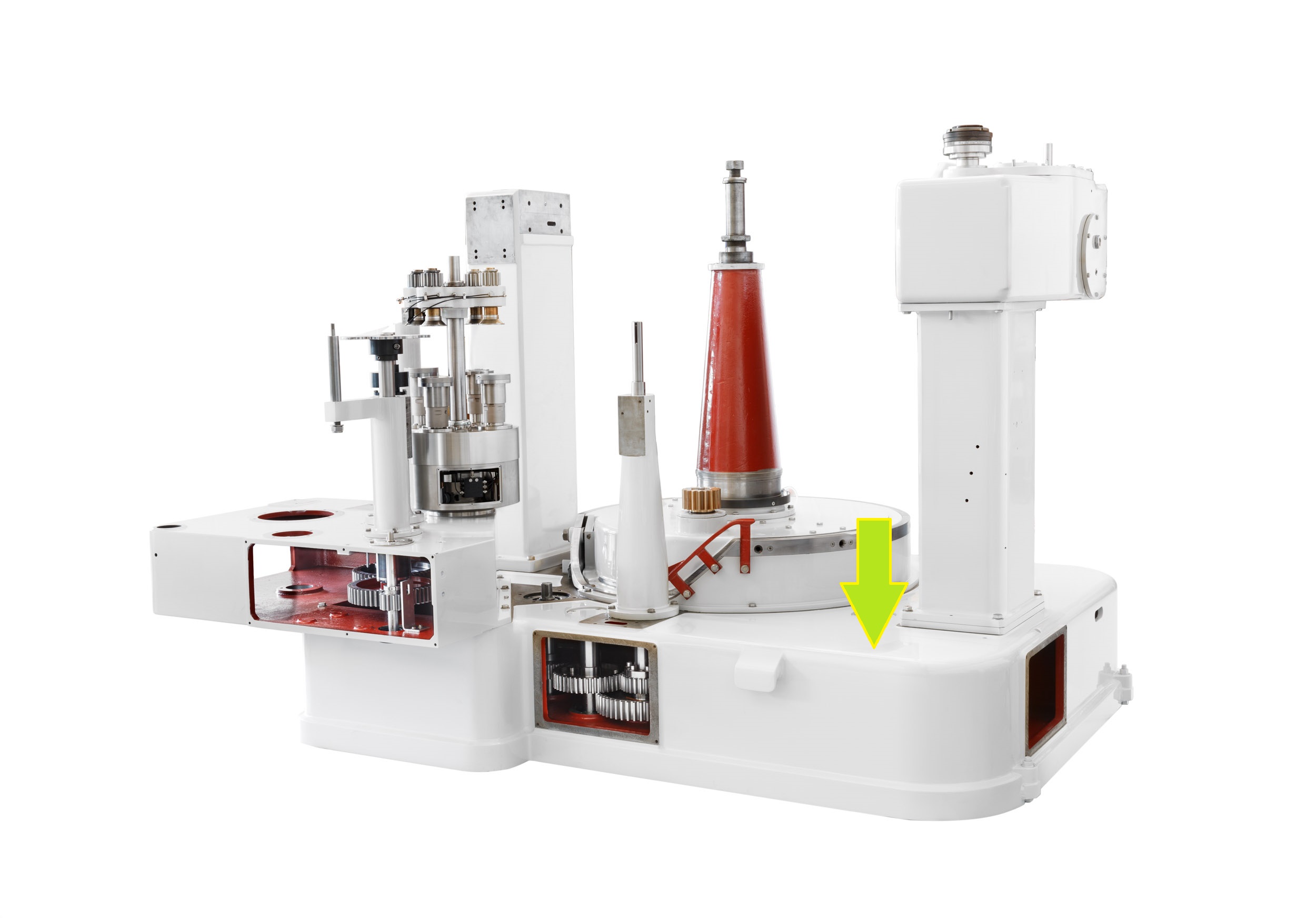

Ferrum FSH Seamer, fully re-manufactured and upgraded.

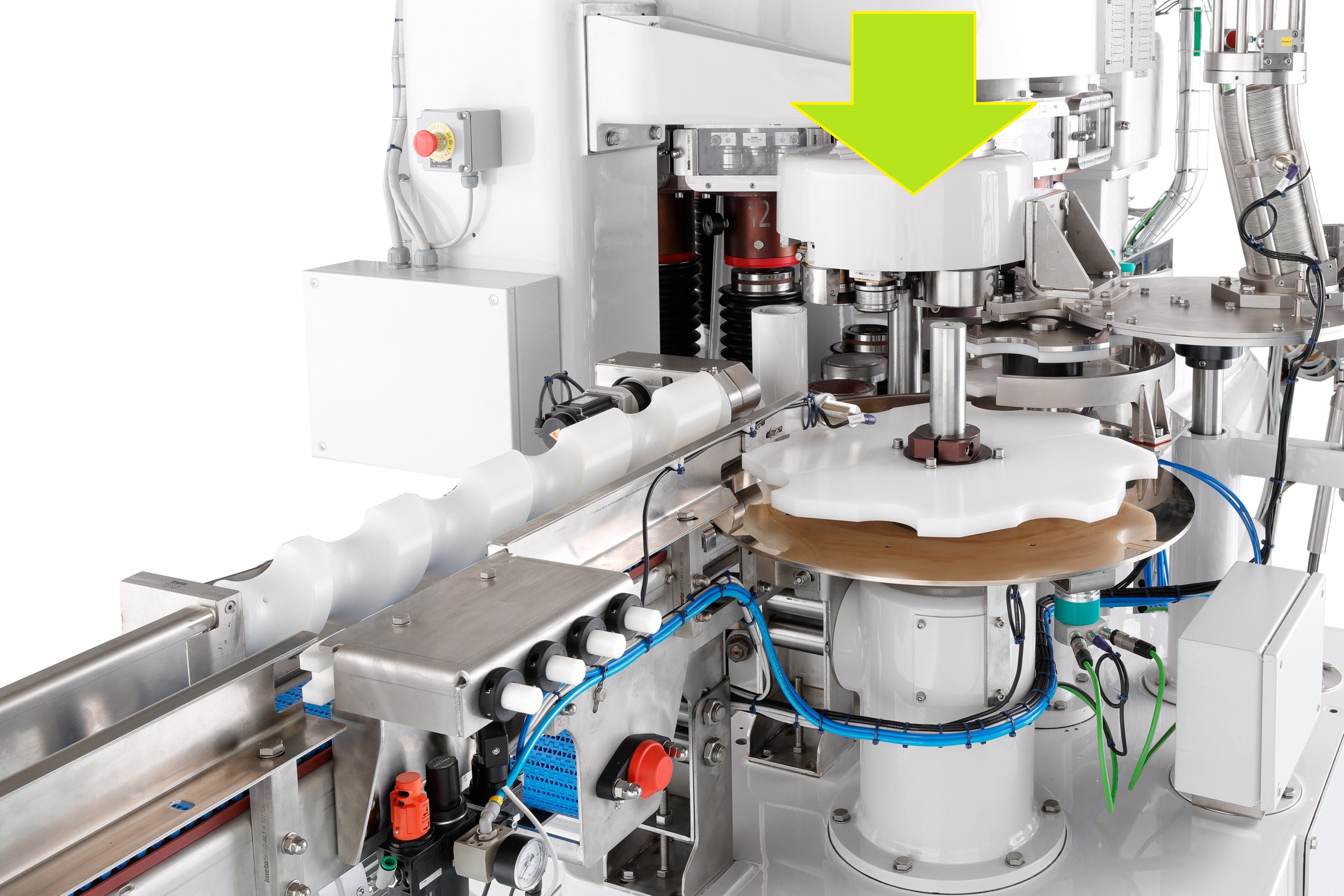

- Can Feeding Table with Self-activated syncro can feeding worm. This enables to shut out every single seaming head during production.

2. Oil seals made by innovative materials and innovative design; they have a better resistance against wear and they are mores efficient against leakage.

3. Extremely smooth surface treatment on all casting parts, highly resistant painting performing as a lacquering, in order to reduce coffee sediments as much as possible so the surface will be easier to clean.

4. Gear driven lifters upgrade of the clinching station, with a fine registration system of the spring pressure, in order to better manage the setting of the clinching.

5. Can Inlet/Discharge main support divided into 3 in order to make any maintenance or setting operation in this part of the machine easier and faster.

6. Sound-absorbing perimetral and upper safety guards to reduce sounds up to 73 decibes at a capacity of 100CPM.

7. Special seaming roll levers with micrometric setting system, both axial or radial.

8. Upper rotor fully redesigned to match the new seaming rolls with micrometric setting system.